1. Sorting

A specialist will divide rough into

groups based on its shape, size,

and inclusions. He determines what

cuts the rough will become to

maximize yield.

2. Sawing

Not every section of the rough is

usable. Cutters will remove large

portions of rough that have inclusions

or color zoning with pliers or a

circular saw.

3. Shaping

The cutter forms the basic profile of

the gem by pressing the rough against

a lap with low grade abrasive to gently grind the gem into shape.

4. Dopping

Preforms are attached to a brass dop

stick with hot wax so that cutters can

facet and polish the gem with greater accuracy and control.

5. Faceting

Cutters form the facets one at a time by

securing the end of the dop in the tang and

pressing the gem gently against the lap.

6. Polishing

After the crown and pavilion are faceted, cutters go back and use a high grit diamond abrasive to polish every facet.

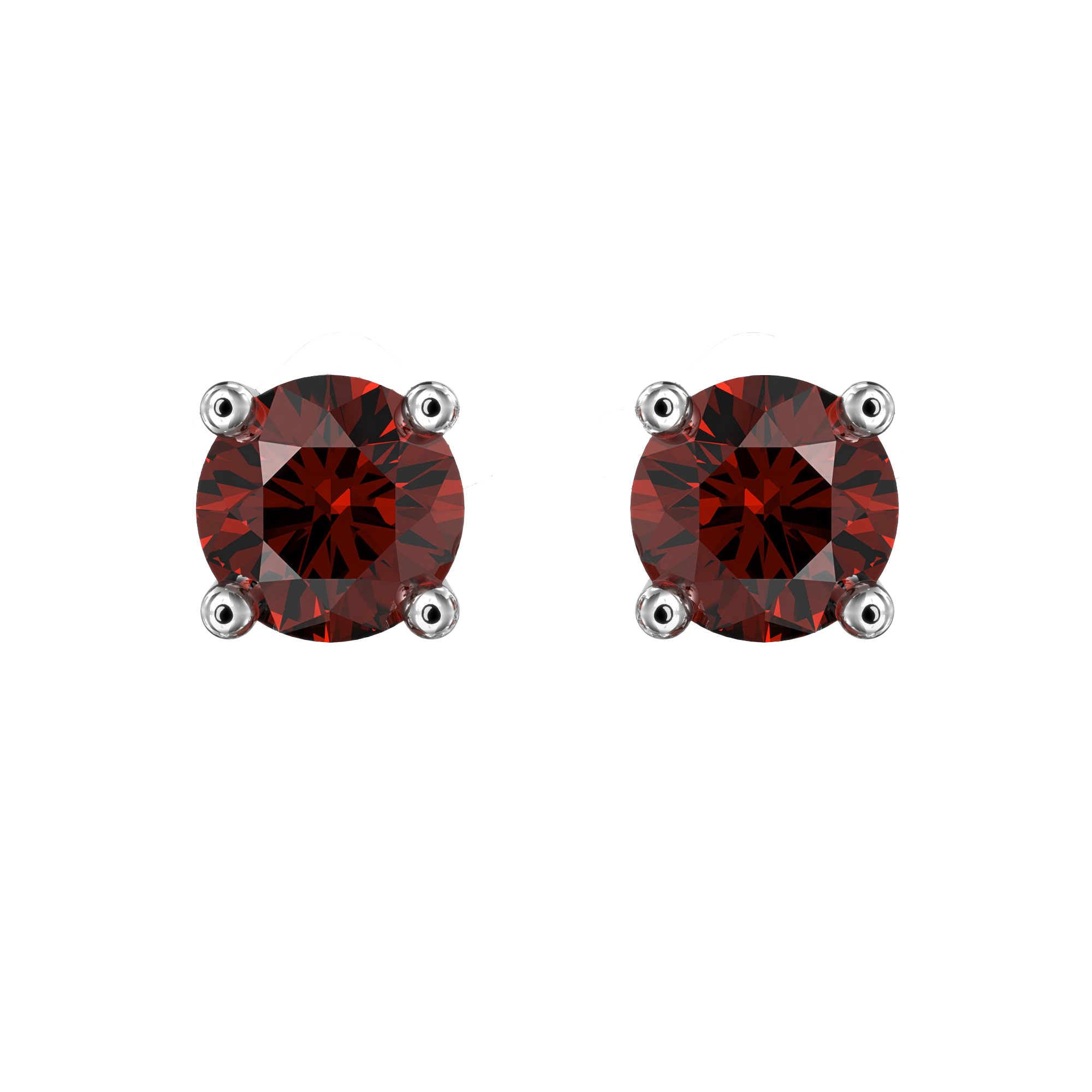

7. Finished

Cutters complete the gem by polishing the

girdle and giving it either one continuous

surface or multiple facets.